ANODE ALUMINUM AND 5 THINGS YOU NEED TO KNOW

ANODE ALUMINUM AND 5 THINGS TO KNOW

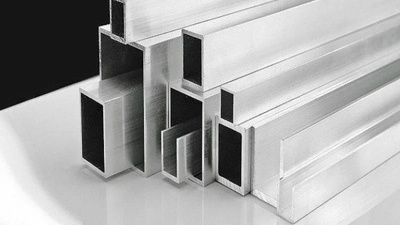

Aluminum anode

What is Aluminum Anode?

Anodized aluminum or anodized aluminum is a surface treatment that makes aluminum hard. through the anodizing process. The anode layer's nature is like the protective film for the profile aluminum bar. It helps aluminum withstand the effects of weather and helps aluminum last longer than usual.

How stable is aluminum anode?

Aluminum anode is high grade aluminum material with excellent hardness. It is this feature that the aluminum anode process is used in many different industries. Examples: automobile manufacturing, aerospace materials industry, construction (steel buildings, doors, windows and glass walls). medical, electronics and home appliances, when comparing aluminum anode with other metals. the anode hardness can be said to be invincible (close to diamond). Trend of modern aluminum and glass doors 2020

How aluminum Anode protects aluminum surfaces

Often on the surface of aluminum bars and aluminum alloy products will form very thin oxide layers by themselves. They are capable of preventing the inner aluminum layer from being oxidized (unlike steel with porous oxide layer, so steel is constantly rusting). However, this oxidized film will be uneven, causing the aluminum surface to lose its inherent luster. In addition, the natural oxidation film has many pores, reducing its resistance to rust. Therefore, aluminum and aluminum alloy products are often surface treated with Anode technology to create a thick layer of oxide on the surface, making it more durable than the natural oxide layer.

How Do People Anode Aluminum?

The electrolysis method is applied to the Anode process. The product is hooked into the caria and then dipped in the treatment tank (anode), the treatment tank contains chemical solutions (cathode). When an electric current flows through the anodized tank, electrolysis takes place, oxidizing the surface of the aluminum to form a durable, hard oxidation layer, protecting the aluminum surface and increasing the hardness of the aluminum bar. See also: The reason you should choose furniture for the family.

Aluminum Anode effect?

Technology Increases the durability of aluminum. The oxide layer created during the anode gives aluminum a protective layer to avoid contact with oxygen in the air, stopping the metal oxidation process. Perfect aesthetics. The aluminum anodization process creates a brighter, more aesthetic surface. Surface hardening. After the anodized aluminum surface is coated with oxidation evenly, making the aluminum surface harder. Effective insulation. Aluminum oxide has good thermal and electrical insulation properties. It is suitable for use as a material for modern buildings.

Do Thanh Aluminum Factory

Grando Aluminum Aluminum - aluminum profile bar with manufacturing factories located in Gia Lam, Hanoi and Hai Duong. Do Thanh Aluminum Factory has the highest rate of automation in the country. Using the most modern production lines and technology in the world. With 9 extrusion lines and powder coating lines. Anode plating from leading equipment suppliers such as Switzerland, Germany, ... The factory has an environmentally friendly production system. Always ensure safety in production and save fuel. Do Thanh wishes to create quality aluminum profiles. outstanding and high aesthetics.