What is aluminium used for?

Discuss why aluminium is a versatile metal

The uniqueness of aluminium’s properties makes it highly versatile. It is lightweight but strong, which is good for making car parts to materials used in aerospace. Moreover, it does not corrode easily thus products made it can last longer. Its excellent electrical and thermal conductivity also means that it can be applied in heat exchangers as well as electrical systems. Furthermore, unlike other metals, aluminum can be recycled without compromise on its properties hence regarded as friendly to environment. These attributes are what make aluminum a vital material across many industries.

Aluminium’s most common products

Unique properties of aluminium result in its use in various products. Below are some of the most common ones;

Foil and Packaging: Aluminum foil possesses excellent malleability and barrier qualities thus widely used for wrapping foodstuffs, drugs among other consumer goods. Technical Parameter: Thickness is usually 0.006 mm -0 .2 mm giving both flexibility and an effective seal.

Automotive Components: Car bodies, engine blocks and wheels are made out of aluminum because it is light weight resulting better fuel consumption and performance respectively. Technical Parameter: The tensile strength of the automotive grade aluminum alloys is generally above 300 MPa.

Aerospace Structures: Aluminum has the highest strength to weight ratio that optimizes performance at minimum possible mass of aircrafts or spacecrafts. Technical Parameter: Aerospace-grade aluminum alloys like 7075-T6 have tensile strengths over 500 MPa.

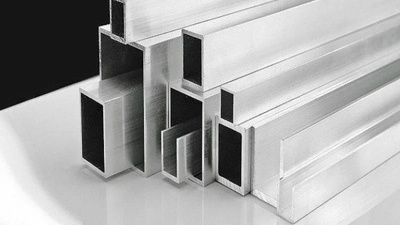

Construction Materials: Windows frames; curtain walls; roofing – all these building elements often contain aluminium elements in them since this material ensures corrosion resistance and long life time for any structure itself . Technical Parameter: Structural aluminum typically maintains a modulus of elasticity of about 70 GPa.

Electrical Conductors: This attribute makes it useful for electric power lines such as cables hence are normally used along with copper wires during wiring installations or maintenance works done by electrical contractors. Technical Parameter: Aluminum has a conductivity of approximately 61% IACS.

Consumer Electronics: aluminum is applied in the outer parts of laptops, smartphones and tablets because it conducts heat away them while at the same time making them look sophisticated. Technical Parameter: Thermal conductivity is approx 235 W/m.K facilitating heat dissipation.

Every application mentioned above exploits the unique technical parameters of aluminum for their advantage thus showing its versatility among several other applications.

Aluminum used in construction

The beneficial characteristics make aluminum one of the most popular materials in construction industry. It is commonly used to make window frames, curtain walls, roofing as well as structural components. The following are examples on how aluminium is used in construction:

Window Frames: Strong, durable and almost maintenance-free qualities of aluminium frames have made them famous. They also provide good thermal insulation and do not corrode easily thus they serve for long time without need for replacement.

Technical Parameter: Structural aluminum typically maintains a modulus of elasticity of about 70 GPa that guarantees no bending or movement in window framing systems.

Curtain Walls: These walls are made up using aluminum to give buildings a modern stylish looks which can also withstand environmental forces within it.

Technical Parameter: High tensile strength characteristic found in architectural-grade alloys makes curtain wallsresist wind loads and other impacts with some alloys having tensile strengths exceeding 200 MPa.

Roofing: Aluminum roofs are lightweight, resistant to corrosion and reflect sunlight hence they help reduce cooling loads resulting energy efficiency improvement.

Technical Parameter:Aluminum’s corrosion resistance arises due to an oxide layer covering its surface protecting any roofing material decay over extended period.T

Structural Components: Aluminium beams, columns etc. are lighter yet stronger than other metals that can be put such uses because it provides favorable strength-to-weight ratio.

Technical parameter: Structural aluminium is noted to have an average density of about 2.7 g/cm³, which is one third of steel thus making it easier to handle and reducing structural loads.

In this application, the technical parameters of aluminum in construction are highlighted as a guarantee for performance, reliability and durability.