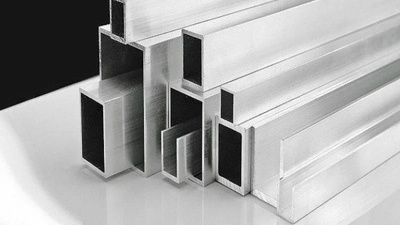

Grando building another Anodization line to serve production

Recently, in order to better serve the domestic and international demand for aluminum profiles, Grando has installed an additional anodization line, increasing anodized capacity by 2,000 tons/month.

Anodization is a surface treatment method through electrochemical processes to create a stable surface with a certain hardness suitable for use in the industrial field. The Anodizing process helps increase the hardness, durability, and aesthetics of aluminum; providing a perfect protective layer against the negative effects of weather and abrasive mechanical impacts.

- Increase aesthetics: Anodized aluminum can be dyed to increase the aesthetics of the product. Thanks to the good adhesion of the anodized coating, the color of the anodized aluminum material after dyeing is very durable over time.

- High abrasion resistance: The anodized coating helps improve the abrasion resistance of the aluminum oxidation layer, making the material less susceptible to mechanical or chemical corrosion, the film hardness can reach over 300 HV.

- Durable coating: The coating color is super durable, does not turn yellow and is always shiny over many years, and is resistant to rust and scratches.

-Dustproof, easy to clean: The smooth, anti-fouling aluminum anode surface makes it easy to clean with water, saving cleaning and maintenance time.

- Insulation ability: The anode coating on the aluminum surface will form a natural insulator, helping to ensure safety during use.

- Heat resistance: Compared to natural aluminum, anodized aluminum has better heat resistance and heat dissipation. In particular, black anodized coating will dissipate heat better than conventional coating.

Grando believes that with a modern, synchronous production line system, the Grando Aluminum brand will lead the Vietnamese domestic market and reach the world.