The role of the gasket when using aluminum and glass doors

The role of the gasket when using aluminum and glass doors

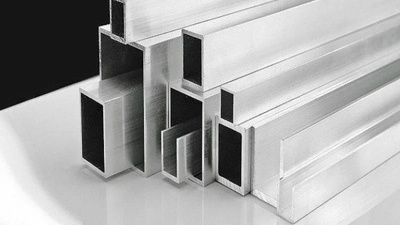

High-grade aluminum doors are favored by consumers thanks to their many outstanding features such as high safety, dustproof, anti-noise, heat insulation, and energy consumption. Here are a few shares about the role of the gasket when using aluminum and glass doors. The close combination of components including: door frames, glass boxes, gaskets and metal accessories is very important.

Properties of various types of Gaskets

Finished gaskets are manufactured from a number of materials such as PVC, Silicone, TPE, EPDM, ... However, each material has its own advantages and disadvantages, ensuring the right choice for different users. .

- Gaskets made from PVC are cheap, have low durability, have poor heat resistance, are easy to wear, break, and easily age.

- Silicone and TPE gaskets are more heat resistant, less affected by the sun's rays, very durable but at a high cost.

- EPDM gaskets are gaskets derived from natural rubber, combined with additives. Go through a process of vulcanization to shape the gasket to make the finished product. EPDM gaskets are durable and affordable to apply in aluminum door manufacturing technology for buildings.

Basically, in addition to gaskets, metal accessories are also important details that contribute to ensuring sound and heat insulation of the door.

Application of Gasket system for Aluminum and Glass doors:

Gaskets for doors, windows are combined with metal accessories to create the tightness of aluminum and glass doors. Good quality EPDM gaskets should be used that are less affected by external weather conditions. EPDM gasket has good elasticity, makes aluminum and glass doors tight, quiet, minimize noise, waterproof and dustproof. The quality depends on the composition of the material as well as the manufacturing process. See also: Learn about aluminum door accessories

Note when using gasket for aluminum and glass doors:

With many production units of aluminum and glass doors, to save investment costs and reduce product costs. They often choose to use poor quality gaskets for construction. Poor quality aluminum and glass door seals quickly harden, brittle, and less elastic, leading to rainwater infiltration into the house and reduce the durability of the door. In addition to gaskets, metal accessories are also important details that contribute to ensuring sound and heat insulation of aluminum and glass doors:

- According to the Vietnam Quality Standard No. TCVN 7451: 2004, the metal accessories system is guaranteed to include “various hinges, flip openers, lock handle / handle, multi-point locking bar and specialized lock.

- Accessories are made from stainless alloy or alloy steel with anti-rust coating, with quality according to current standards, ensuring tightness, durability and safety for the door after assembly ”.

The effect of metal accessories

Currently, there are many types of doors that open inward, turn outward, swing open, swing open - flip inward, slide open, open parallel ... Choosing the right metal product will create the ensure safety for the project. The metal fittings are manufactured from the better the material, the higher the tightness. Metal accessories system increases the durability of the door set during operation and prevents penetration. In addition, for each set of doors of each project, homeowners can choose metal accessories that suit the needs and budget of the project. To get a good door set, you should choose not only door frames and glass but also gaskets and standard metal accessories. In addition, the construction and installation process also plays an important role in maximizing the advantages of the door. Above are some sharing about the role of gaskets in soundproofing, insulation of aluminum and glass doors. See also: Things to know about profiled aluminum