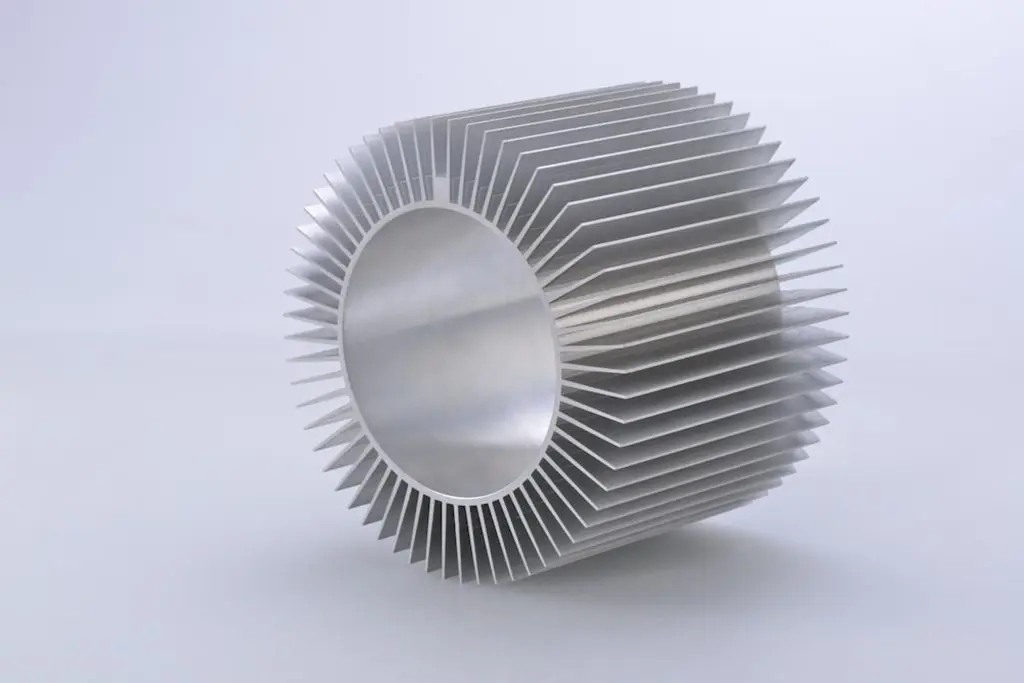

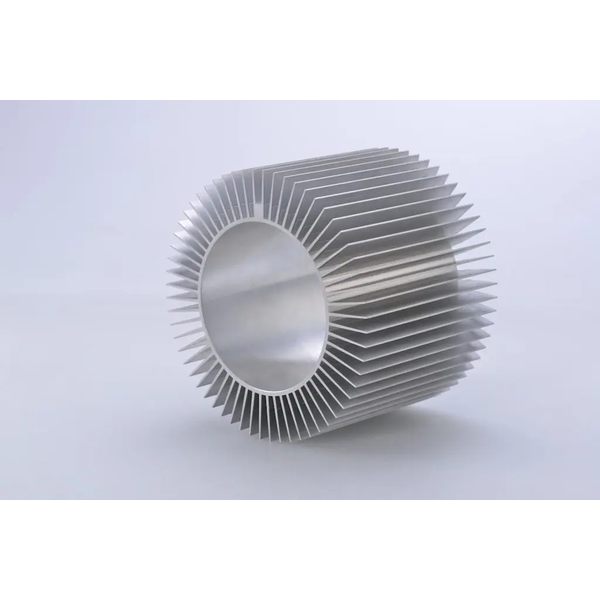

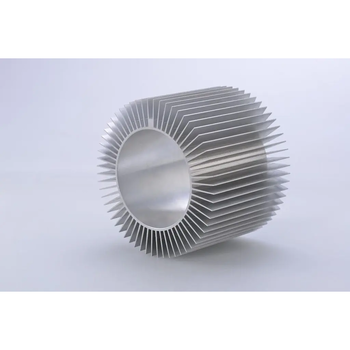

Aluminum extruded heat-sink

In the world of modern electronics, thermal management is an essential aspect of ensuring the optimal performance and longevity of electronic components. As electronic devices become more powerful and compact, the need for efficient heat dissipation methods becomes even more crucial. One such solution that has gained significant popularity in recent years is the use of aluminum extruded heat sink technology.

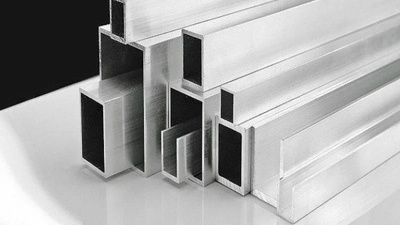

Aluminum extruded heat sinks are designed to absorb and dissipate heat generated by electronic components, such as processors, power supplies, and LEDs. The process of aluminum extrusion involves the shaping of aluminum material a specific profile or shape that is optimized for efficient heat dissipation. As a result, aluminum extruded heat sinks can provide a high level of thermal conductivity and passive cooling, making them ideal for a wide range of applications in the electronics industry.

This article will explore the process of aluminum heat sink extrusions, the key characteristics of aluminum extrusion heat sinks, and the advantages they offer over other heat sink solutions. It will also delve the applications of extruded heatsinks in modern electronics, as well as the customization options available for heatsink aluminum extrusions. Finally, it will discuss best practices for selecting and designing extruded heat sinks and provide an overview of the future of aluminum extruded heat sinks in the electronics industry.

AAdministratorsQTV

Welcome, honored guests. Please leave a comment, we will respond soon